Plastic products are the most widely used products in the current society. They cannot be separated from the participation of plastics in consumer consumption, industrial and agricultural production, household appliances, public service construction, and military industry. Designers often spend a lot of time choosing the right plastic materials. In order to save the designer’s time, based on my years of experience in plastic product design, I summarize how to quickly select product materials. Hope it will be helpful to those who are engaged in these industries.

1. According to the environment

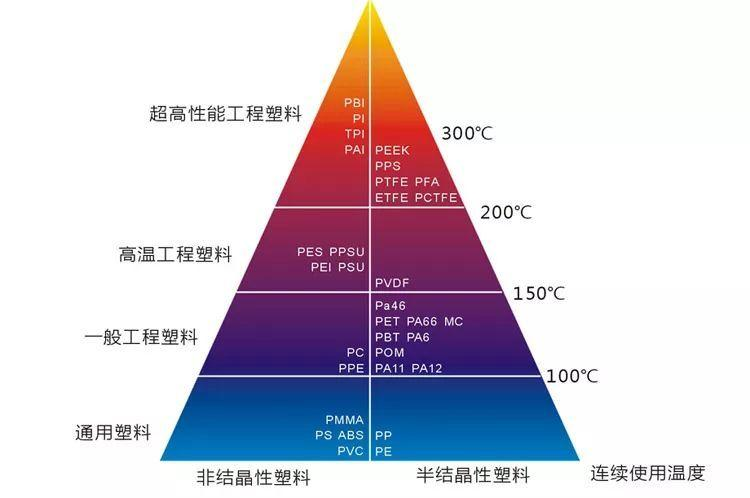

The use environment refers to the temperature, humidity, medium, etc. of the surrounding environment when the material or product is used. The temperature and humidity conditions are determined by the surrounding contact medium. In addition, in addition to wind, rain, fog, etc., natural exposure is also affected by factors such as sunlight and chemical substances. Therefore, it is necessary to consider the environmental adaptation of plastics.

2. According to the force type and mode of action of plastic products

Under the action of force, the product will inevitably produce deformation, which is mainly manifested as tension, compression, bending, twisting, shear, impact, or a combination of several forces. In addition, if the external force is an impact force and additional work is required for the production, a plastic with high impact strength must be selected; if it is a static force, a material with a small creep should be selected; if it is a force of repeated deformation of the plastic, you can only choose Material with good fatigue strength.

3. According to the object of use

Different regions, countries, and races have differences in quality standards, environmental protection directives, aesthetic concepts, and hobbies. When choosing plastics, it should meet the requirements of the product sales area.

1. Production of plastic products such as shells, boxes, covers and tubes

Such plastic products should not bear large external forces, and have excellent impact strength, hardness, suitable tensile strength, dimensional stability, and acid-base suitability of the product to the external environment. In certain occasions where metals cannot be used, plastics can be used for eugenics. Plastic is more suitable for the following situations.

a. Must prevent resonance and require low sound transmission;

b. Requires elastic deformation to prevent dents caused by accidental collisions;

c. The shape of the product is complex, and it is difficult to produce with metal processing technology;

d. The product does not want post-processing;

e. The product is required to be electrically insulated (or partially insulated) and thermally insulated as a whole, or to be colored as a whole or to be transparent or translucent;

f. Requires corrosion resistance, moisture resistance, and no rust;

Post time: Dec-20-2021